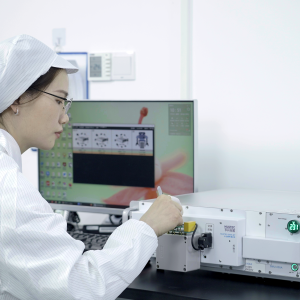

Ensure that the quality of each electronic component is reliable

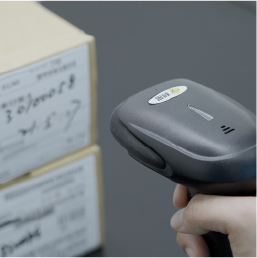

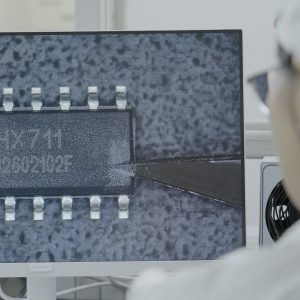

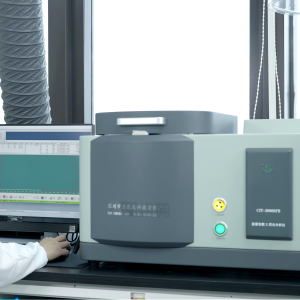

Depend Electronics has an independent anti-counterfeiting testing laboratory, equipped with advanced high-precision testing equipment both at home and abroad in the industry. It combines destructive, non-destructive, and customized testing solutions, etc. All products will undergo a strict multi-step inspection, and these procedures ensure that our customers receive only genuine and functional electronic components.