SSTDP Quality Operation System, created to guarantee the quality of electronic components

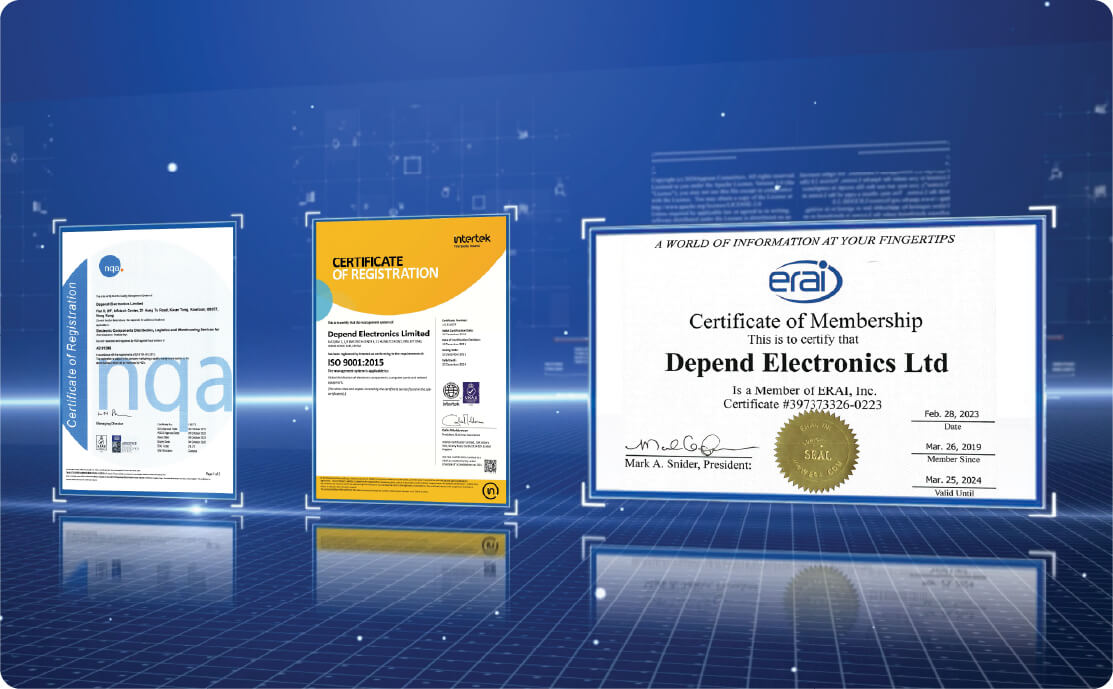

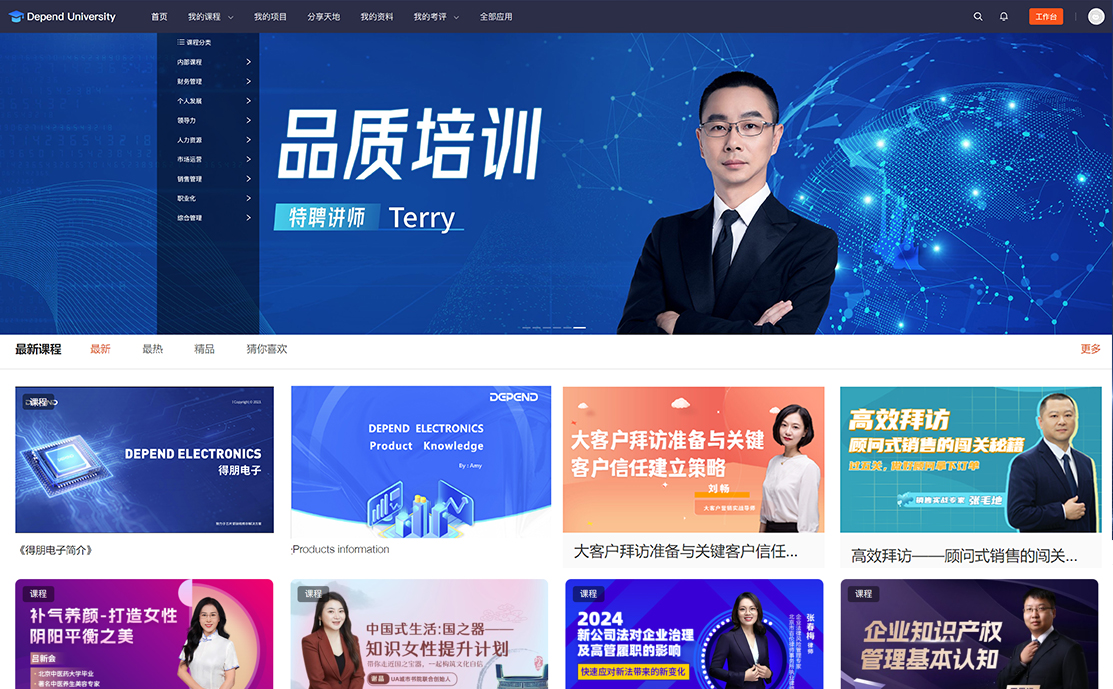

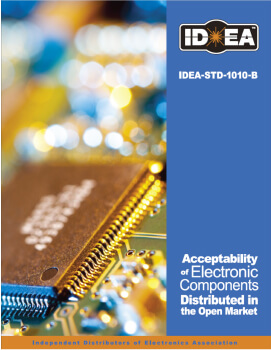

Depend SSTDP is a quality assurance framework developed for counterfeit prevention. It combines industrial leading test standards and methods with sustained growth of database, we continuously optimizing the quality initiatives we've promoted over the years with best practices across the industry.